Jac Cameron's Jeans

The consulting designer behind so many of our favorite brands has a new line that's all her own.

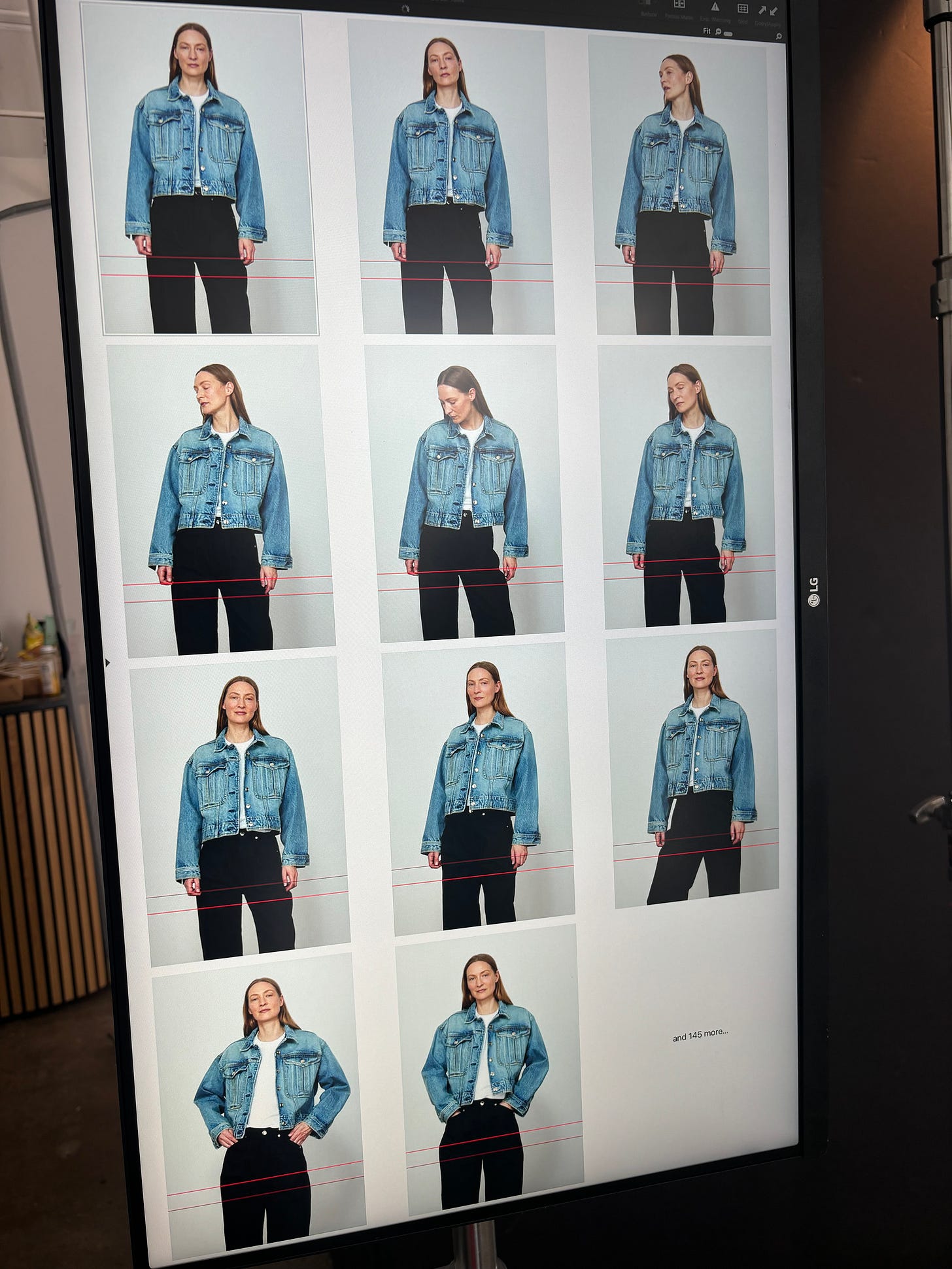

The minute I heard that Jac Cameron was launching her own line of jeans I started plotting this post. Jac, a veteran denim designer who worked at Madewell and Calvin Klein before co-founding Ayr in 2012, has been pretty quiet in recent years, consulting for brands like Apiece Apart and Alex Mill. Now, with the launch of Rùadh she’s speaking up, specifically about how beautiful a denim collection driven by sustainability can be. I know I’m not the only one listening closely.

“My mission was really just to bring this back to a feeling of craft. Small batch,” Jac told me over a video call last week. “It took a long time to launch Rùadh. There are elements of each of my washes that are done by hand.”

Based in New York, Jac currently makes everything in Los Angeles at a factory best-known for its progressive manufacturing practices, and she’s committed to becoming a B Corporation – “the gold standard in sustainability,” she explains. Even the hardware is made from recycled materials. And the jeans? Well, the jeans are what you might expect from someone who has worked with some of the best and biggest denim companies in the world. In a word, they’re outstanding. (I have the Quinn in my usual size 24 and love its mix of rigidity and louche-ness.)

Here, Jac and I talk about her process, her past, the future, and why Rùadh is such a dream come true.

Jane: Let’s start with the name. What is Rùadh?

Jac: It’s Scottish. Gaelic (pronounced Roo-ah). I’m from Scotland, that’s where I grew up, and I wanted this brand to be from the heart, inspired by the landscapes of my childhood. Rùadh means red, which I love. It’s associated with concepts of strength and quiet resilience, and it’s used colloquially for “little red head.” (For all the redheads out there.) I just love the color red, it’s a powerful color. It’s a name with depth, which felt very right for this. And also, you know, it’s incredibly difficult to trademark anything [laughs], so I thought, OK, a Scottish Gaelic name. There really can’t be too many brands with a Scottish Gaelic name, and it worked out.

Jane: And you didn’t want to give it your own name?

Jac: No. I thought about it. But I wanted to give it a name that had its own connotations.

Jane: I want to talk about Ayr for a moment because it’s such a great brand that makes such great jeans and you were one if its co-founders. Remind me, when did Ayr launch?

Jac: I started working on it in 2012. We were working on it for one calendar year before we launched.

Jane: I can’t believe that was more than a decade ago. I think about who I was ten years ago and I am the same person in some ways – I still nerd out over washes – but I’m also a really different person. I’ve had two children. Literally my brain has changed. What’s different for you now, ten years after you started Ayr? How have you changed? And what has stayed the same?

Jac: I just have a very different way of thinking about building things now. Today, I won’t work on anything that I don’t personally feel has value. And I’m lucky enough that I don’t have to take every job. I want to put product out there that is valuable in someone’s hands. I don’t just want to make stuff that has a big margin.

Everyone says that the customer is their north star, and the greatest learning for me being at Ayr – you know, we opened a store on Lafayette and I used to spend my weekends there. I loved working with the customer. I loved fitting people in jeans. I loved talking about the process. That human connection was something that I never really had at any other brand. I would love love love one day to have a store of my own. With Rùadh, I had all of my friends come and try stuff on [during development]. We did critiques, and that’s when you really get to learn, working with people when they have it on the body. I have a real passion and love for doing this. Otherwise, I wouldn’t be in it. It’s a crazy industry! But I love everyone I work with. All of the kooky people that make up the product at every point in the journey. I love building community. My 3PL, I love them, I’ve never worked with them before, they’re brilliant. Working with really awesome great talented people and letting them come to the table with opinions that you hear and translate. I like to give my team the autonomy to make decisions. I’ve worked with my tech designer for so many years. There’s a level of trust with everyone that I’ve brought into this that feels really nice.

“I used to spend my weekends [at the Ayr store on Lafayette]. I loved working with the customer. I loved fitting people in jeans. I loved talking about the process. That human connection was something that I never really had at any other brand.”

Jane: You left Ayr 3 years ago, is that right? Have you been working on Rùadh since?

Jac: No. I met with my factory in Los Angeles in February of last year. I went to them and told them that I only wanted to work with them because I wanted my brand to be as sustainable as possible at this moment. [It’s a B Corp factory called Saitex.] Shortly thereafter I started trademarking, and that’s when I started putting pen to paper, working with fits, and building out my tech pack. Last April was when I really started.

Jane: What were you doing in between?

Jac: For the two years before that I was consulting, and I’m still consulting. But for two years I did a whole bunch of brands. It was honestly the best experience ever because when you live in the bubble of one place and you’re building it the way I was with Ayr, it was just nose-to-the-ground getting through tech packs and the daily stuff. But then, it was like I poked my head out when I started consulting. I was working for like eight or nine other brands. I worked constantly for two years, and it really made me think. I started writing things down for myself. Saving tears. I was buying vintage. I didn’t have any intention to start my own brand, but then the idea became something that I couldn’t ignore. It kept me up at night, and it niggled at me. So I started sketching and that’s when I knew that I had to do it.

Jane: Sustainability is really important to you and your B Corporation certification is pending. Why be a B Corp?

Jac: It was important for me to be B Corp from the very beginning. I’m launching with denim, but I want to do a new category every season going forward. So, for Spring ‘25 I’m making organic cotton knits out of Portugal, and I’m working on hand-knit sweaters made in Scotland, and I’m doing some development on woven pieces out of Italy…

I trust my denim factory [Saitex]. I know that they’re using Blue Sign-approved chemicals, I know that they have a closed loop water system, so you have 97% water savings. They’re working with ozone and they use all Jeanologia [laser] technology. I know this because I have worked with them forever, and I would say they are at the forefront in terms of a sustainable denim laundry. For me, it was a no-brainer to work with them. But I wanted B Corp certification for my own company because as we bring in other factories – for knits and hand-knit sweaters, and wovens – it gets a little more challenging to maintain those high bars.

I worked with a sustainability expert – her name is Liz Hershfield – and she’s helped me with getting the certification. I don’t know if you’ve looked at the process, but it’s like doing my Green Card paperwork, times ten. Liz really helped me, even from a raw materials and sourcing perspective for some of these new categories. Of course, I know that organic cotton is better than BCI cotton [which monitors chemical use, but is not free of chemicals]. But I went hard after regenerative cotton for denim. I also want to support the back side by donating to charities like The Soil Health Institute, which help the farmers transition over to regenerative cotton and regenerative farming techniques. For me, it’s about putting something out there that has both a light footprint and also helps support communities.

Jane: What makes a B Corp a B Corp?

Jac: At the moment we are B Corp Pending certified. We are "pending" status currently as we have less than one year of operations. The process to become B Corp is very involved and incredibly detailed. It's designed to measure your impact across many categories. Is your team diverse? What practices are you looking at as a company? The source of lightbulbs that you’re using? The amount of water that you’re using as a business? What is your output and how is that being measured? Is your sourcing regenerative, etc? All of these things are markers that are considered in attaining B Corp status.

Jane: And is all of the denim you use made from regenerative organic cotton?

Jac: I’d say 85% of my collection is made from regenerative cotton. I do have one denim quality that’s Japanese, it’s BCI cotton. It’s the most beautiful, most stunning fabric that I’ve ever seen in my life. It’s in the Quinn jean. I’m wearing it now. It’s a high rise straight leg, but it’s relaxed. You can go your true size, or you can size down. It’s a 15oz rigid, and the fit intent was to feel like it had ease built in. So it doesn’t feel so constricting. I worked off of a couple of different vintage pairs to help perfect my rise shapes and then we tweaked the patterns. That’s hardest part – building a great jean fit is all in the rises. So I did a lot of work with pattern makers to perfect that. It’s one of my favorite fits in the line.

The leg shape on the Quinn is one of the most beautiful straight-leg leg shapes. Sometimes you get these leg shapes that have a little curve on the inseam and that’s my pet peeve in life, any shaping on the inseam of a straight leg just ruins it. It takes it to a flare in my mind. The leg is very straight, but it’s a fuller straight. And it’s all shipped in trouser fold, so it’s hard pressed.

“The leg shape on the Quinn is one of the most beautiful straight-leg leg shapes. Sometimes you get these leg shapes that have a little curve on the inseam and that’s my pet peeve in life, any shaping on the inseam of a straight leg just ruins it.”

One of the things I was thinking about when I was building this were the days when people used to starch their jeans and press and fold them. My mom still does that. It’s how people cared for their jeans. Almost everything with Rùadh is shipped trouser pressed with the hard crease down the center. It just makes it feel a little bit more elevated and special.

Jane: And you have a felled seam on the outer leg of the Quinn. I love that.

Jac: I love it too. It’s such a nice detail.

Jane: And the Archer?

Jac: The Archer is a very baggy trouser style jean and it anchors at the waist but there is a curve built from the waist into the leg shape. When we started fitting this I was like, Okay this could go wrong. Let’s try it and see. We then added the pleat. It’s in a 13oz rigid, it’s a stiff, heavy fabric. But that jean has been the most popular, actually. That and the Constance jacket. Oh, and the Staffa skirt, which I didn’t expect. The skirt is very cute. It’s also surprisingly sexy. It’s a high-rise tight little thing, and in my imagination it was going to be a lower rise and a bit more relaxed, but then we tightened it up and it became a bit more sexy. We styled it for the shoot back to ankle socks and hiking shoes and that’s the way I wear it.

Jane: And your stretch style is called the Kerr…

Jac: The Kerr is a true high rise. It is interesting because it’s the tightest and closest to the body, so you really use that stretch. It’s a nice opening price point and it really works in black.

Jane: You know I love details, tell me about your buttons and hardware.

Jac: All of my hardware was made in Italy, so I had this idea to make my hardware feel like jewelry. It’s a semi-precious button with a real gold finish. It’s stunning, like, I want to make it into earrings! And I did a rivet with a silver disc and a gold nail just to do a bit of metal-mixing. This is the stuff I really dive into. And I’m like, does anyone see this?

Jane: They might not know it, but I think they do.

Jac: Hopefully it will be felt. But my hardware is also 80% recycled brass, 100% recycled stainless steel backers. I sourced everything and did production for this first collection completely myself. I worked with consultants on tech and PR, marketing, all of that. But the product piece came 100% from me. It came from the heart.

As I work forward, it all starts with the fabric. You live in something and when you know it’s a slam dunk then you start thinking about what fit you can put it in. You can have an idea for something, but then you live in the fabric and you’re like, Oh, it’s going to have to go this way or that way.

Jane: I get it. I fell in love with the fabric that I made my jumpsuits in and so I started cutting it in everything – every jacket, every pant. It’s also really interesting when a fabric, suddenly in a new thing, looks so wrong. It’s incredible how amazing that fabric was for my jumpsuit and how horrible it is in a jacket. The fabric really has a destiny.

Jac: And then when you add in wash as another layer, it takes it to a different place entirely. It’s a really tenuous process.

Jane: But when you find the ones that work, that’s your business. Your customers love it and you can depend on it.

Jac: It’s interesting. You know the brands and what they stand for because of their fabric. Mother is high-power stretch. Frame, stretch. AGoldE, rigid. But they do that 1% comfort stretch, but they are thought of as a rigid brand. You have to go out there and put your foot forward in what you want to be known for and I think relaxed rigid is the theme of my collection.

Jane: You have so much experience making jeans. What did you learn here that you had never experienced before?

Jac: It might not answer the question, but putting your own thing out there – the fear and having gone through the whole process of building this – just the feeling of intense joy, heart full intense joy at having the opportunity to do it. That’s new for me. And then to bring in the people I love working with. I just feel incredibly grateful. To take my team to Elgin, in the middle of nowhere, the north coast of Scotland and shoot it! When I talk about dreams being realized, this is it. And it’s also nice because it’s truly mine. I love designing for other people, I love tailoring my designs to fit their customers and their needs. But this is really mine and I just feel incredibly lucky.

Wishing everyone a restful weekend. Wear your favorite jeans and be happy. Thanks for reading and, as always, denim forever.

Jane

More good links…

Game-changing underwear, here.

AGoldE’s beloved low slung puddle is currently on sale at Net-a-Porter.

The General Election is on November 5. It’s really easy to check your voter registration and/or register to vote at this link.

Grateful for you, Jane. You keep us in the know on all of it. One day I would love your denim wishlist from all the brands you look at! Like after you do these interviews what’s the one piece you have your eye on? 😚

thank you for this!! and I saw your tailored Quinn’s. love them but I am so torn between the Rhône and the Quinn!!! advice? I am tall…5’10”+ and about 125lbs.